Control Charts

The control chart is a graph that represents the variability of a process variable over time. Control charts are used to determine whether a process is in a state of statistical control, to find the causes of changes in a process, and monitor process performance. Control charts are also known as Shewhart control charts, after W.A. Shewhart (1931) who first introduced the concept.

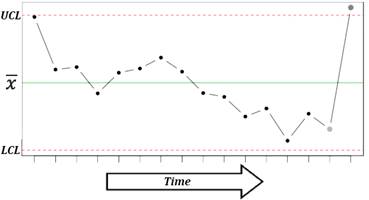

A control chart consists of:

· A center line, drawn as a green line at the mean value for the in-control process (stable zone).

·

Upper and lower control limits (UCL and LCL) – red lines.

These control limits are chosen so that almost all of the data points will fall

within these limits as long as the process remains in-control. Control limits are

set at a distance of three sigma 3![]() (standard

deviation) above and below the mean centerline. Default distance (3

(standard

deviation) above and below the mean centerline. Default distance (3![]() ) can be

overwritten using the “Control limits at these

multiples of standard deviations” option.

) can be

overwritten using the “Control limits at these

multiples of standard deviations” option.

· Data points representing a statistic for a subgroup (mean, range, proportion) or an attribute. A point outside the control limits indicates the presence of a special cause that deserves investigation.

There are two basic types of control charts – control charts for attributes and control charts for variables. Following types of control charts are available:

Individuals and moving range charts

Control charts for subgroup averages

·

X-bar ![]() chart

chart

· R chart

· s chart

Time weighted control charts

· CUSUM chart

Control charts for attributes

· P chart

· C chart

· U chart

X-bar chart

X-bar ![]() chart is used

to monitor the mean value of a process over time (between-sample variability).

For each subgroup, the mean value is plotted.

chart is used

to monitor the mean value of a process over time (between-sample variability).

For each subgroup, the mean value is plotted.

Run: Charts→[Control Charts] X-bar and R Chart or X-bar and S Chart command.

Input variables: please see the Data layout for Xbar-R and Xbar-S charts section below for more details.

R chart

R chart is used to monitor the instantaneous process variability

at a given time (within-sample variability). Standard deviation, approximated

by the sample range is used as a measure of variability – for each subgroup,

the range ![]() is plotted. R

charts are usually used when we have a constant and relatively small sample

size (N=2…15). R chart can be produced for subgroups with a sample size up to

50.

is plotted. R

charts are usually used when we have a constant and relatively small sample

size (N=2…15). R chart can be produced for subgroups with a sample size up to

50.

Run: Charts→[Control Charts] X-bar and R Chart command.

Input variables: please see the Data layout for Xbar-R and Xbar-S charts section below for more details.

Methods

The default (Rbar) estimate

for sigma is ![]() , where K is

the number of subgroups,

, where K is

the number of subgroups, ![]() is the

unbiasing factor. Minimum variance linear unbiased estimate can be selected

from the Advanced Options [v6.5+].

is the

unbiasing factor. Minimum variance linear unbiased estimate can be selected

from the Advanced Options [v6.5+].

S chart

S chart is similar to R chart, but the standard deviation is directly estimated. S charts are preferable when a sample size is a variable or moderately large (N>10).

Run: Charts→[Control Charts] X-bar and s Chart command.

Input variables: please see the Data layout for Xbar-R and Xbar-S charts section below for more details.

Methods

The default (Sbar) estimate

for sigma is ![]() , where K

is the number of subgroups,

, where K

is the number of subgroups, ![]() is the

unbiasing factor.

is the

unbiasing factor.

Data layout for Xbar-R and Xbar-S charts

Use the Data layout option to select how your data is organized.

|

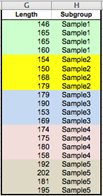

1. Subgroups are defined by values of the Group variable

Select the Length variable as Measurements and the Subgroup variable as (Data Layout #1) Group. This layout allows using subgroups with unequal sizes. |

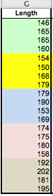

2. Single column with measurements, fixed subgroup size

Select the Length variable as Measurements and enter 4 to the (Data Layout #2) Subgroup Size field. |

|

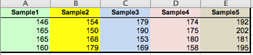

3. Subgroups across the columns, each column represents a subgroup

Select the Sample1–Sample5 variables (columns A:E) as Measurements. This layout allows using subgroups with unequal sizes. |

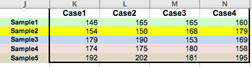

4. Subgroups across the rows, each row represents a subgroup

Select the Case1–Case4 variables (columns K:N) as Measurements. |

Workbook with samples is available through the Dataset link at the top of this page.

CUSUM chart

CUSUM chart (cumulative sum

control chart) is used for change detection monitoring. While control charts

for subgroup averages (X-bar, R and S charts) use information only from the

last sample and can detect process changes greater than ![]() , CUSUM chart,

introduced by (Page, 1954), uses information given by the entire sequence of samples

and thus can detect smaller shifts and maintain tight control over a process.

CUSUM is one of the most powerful management tools available for the detection

of trends and slight changes in data.

, CUSUM chart,

introduced by (Page, 1954), uses information given by the entire sequence of samples

and thus can detect smaller shifts and maintain tight control over a process.

CUSUM is one of the most powerful management tools available for the detection

of trends and slight changes in data.

The cumulative sum of the deviations between each data point (a sample mean) and a reference value – target (T), is plotted. For the rth sample the cumulative sum is defined as:

![]() , where T is

the target. The choice of the T value depends on the application of the

technique. Upper and lower control limits are computed as follows:

, where T is

the target. The choice of the T value depends on the application of the

technique. Upper and lower control limits are computed as follows:

![]() .

.

Allowance K is often chosen about halfway between the target T and the out-of-control value of the mean that we are interested in detecting.

Run: Charts→[Control Charts] CUSUM Chart command.

Select a variable with group codes and a variable with measurements.

Specify the target or

check the “Auto Select Target” option to use

the grand mean as the target estimate. A grand mean is calculated as ![]() .

.

Specify the decision interval H (control limits). Default value of H is 4.

Specify the allowance K (also known as a slack value). Default value of K is 0.5, to detect one-sigma shifts in the mean.

Specifies which subgroup to center the V-mask on. The subgroups have indices starting from 1. Leave the default value – zero, to use the last subgroup.

P chart

P chart is used to monitor the proportion of defectives in a

process. The sample fraction nonconforming (proportion of defectives) is

defined as the ratio of the number of nonconforming units ![]() to the sample

size

to the sample

size ![]() :

: ![]() . The random

variable

. The random

variable ![]() follows binomial

distribution. The mean of

follows binomial

distribution. The mean of ![]() is

is ![]() and the

variance of

and the

variance of ![]() is

is ![]() . The control

limits are defined as

. The control

limits are defined as

![]() .

.

Run: Charts→[Control Charts] P Chart command.

Select a variable with subgroups sample size and a variable with defectives count (measurements) for each subgroup.

If the true fraction conforming p is known – specify the target value. When p is not known it is estimated with the grand mean.

C chart

C chart is used to monitor

the total number of nonconformities per unit ![]() . Unlike the P chart, the C chart allows having more

than one nonconformity per inspection unit, and requires a fixed sample size. The

random variable

. Unlike the P chart, the C chart allows having more

than one nonconformity per inspection unit, and requires a fixed sample size. The

random variable ![]() follows

Poisson distribution.

follows

Poisson distribution.

Center line is defined as ![]() . It is estimated as the observed

average number of nonconformities (grand mean), and control limits are

defined as

. It is estimated as the observed

average number of nonconformities (grand mean), and control limits are

defined as ![]() , where

, where ![]() is set to 3 by default. If the lower

control limit is negative, then there is no lower control limit.

is set to 3 by default. If the lower

control limit is negative, then there is no lower control limit.

Run: Charts→[Control Charts] C Chart command.

Select a variable with measurements (number of nonconformities per unit).

U chart

U chart is used to monitor the average number of

nonconformities per unit ![]() . With U chart we

can have several inspection units in a sample. Center line is defined as

. With U chart we

can have several inspection units in a sample. Center line is defined as ![]() .

.

Run: Charts→[Control Charts] U Chart command.

Select a variable with subgroups sample size and a variable with defectives count (measurements) for each subgroup.

Individuals and moving range I-MR charts

Individuals control chart (I chart)

is used for process monitoring based on individual observations. The center

line represents an estimate of the process average (when unspecified, the

average of all the observations, grand mean, is used), and points on the

chart are the individual values. Control limits

are defined as ![]() , where

, where ![]() is an average of the moving ranges,

is an average of the moving ranges, ![]() is the

unbiasing factor and

is the

unbiasing factor and ![]() is set to 3 by default. Individual charts are

less sensitive (i.e., less powerful) than Xbar and R charts, and the assumption

of normality is more critical (deviations from normality may lead to elevated

rate of false alarms).

is set to 3 by default. Individual charts are

less sensitive (i.e., less powerful) than Xbar and R charts, and the assumption

of normality is more critical (deviations from normality may lead to elevated

rate of false alarms).

Moving range chart (MR chart)

monitors the between variation over time. Moving ranges represent point‑to‑point

variation and are defined as the absolute differences between consecutive

points. The number of points used to calculate a moving range is the moving

range length or span. For the default span value of two, ![]() are defined as

are defined as ![]() . Points on the

chart are moving ranges

. Points on the

chart are moving ranges ![]() and the center line is an average of the moving ranges

and the center line is an average of the moving ranges ![]() . Control limits

are defined as

. Control limits

are defined as ![]() (

(![]() is set to 3 by default). Moving range chart may show cycles

or pattern of runs induced by correlation of moving ranges (Montgomery,

2005) and thus should be treated cautiously.

is set to 3 by default). Moving range chart may show cycles

or pattern of runs induced by correlation of moving ranges (Montgomery,

2005) and thus should be treated cautiously.

Run: Charts→[Control Charts] Individuals and Moving Range command.

Select a variable with measurements.

Optionally, change the method of estimating sigma.

References

Montgomery, D. (2005). Introduction to Statistical Quality Control. Hoboken, New Jersey: John Wiley & Sons, Inc.

Oakland, J. (2007). Statistical Process Control, 6th edition. Butterworth-Heinemann.

Page, E. S. (1954). "Continuous Inspection Scheme". Biometrika. 41 (1/2): 100–115.

Shewhart, W.A. (1931). Economic Control of Quality of Manufactured Products. Van Nostrand, New York and MacMillan, London (501 pages).

Wheeler, D. J. (2010). Individuals Charts Done Right and Wrong, Quality Digest.